Chain Link Fence Installation Guide

Detailed chain link fence installation guides in PDF format, alongside helpful video tutorials, are now readily available from manufacturers like Peak and Modern Fence Technologies.

These resources offer step-by-step instructions, covering everything from material calculation to final safety checks, ensuring a successful project.

Accessing these PDFs and videos will streamline your installation process, providing visual aids and comprehensive guidance for a durable and secure fence.

Chain link fencing remains a popular choice for residential, commercial, and industrial applications due to its affordability, durability, and security. Installation guides, often available as PDFs, are crucial for a successful project, detailing everything from initial planning to final tensioning.

Understanding the basics – post spacing, mesh gauge, and gate hardware – is paramount. Modern Fence Technologies and Peak Chain Link Fencing offer comprehensive resources, including downloadable PDFs and instructional videos, simplifying the process. These guides emphasize safety, adherence to local regulations, and proper material selection.

A well-installed chain link fence provides long-lasting perimeter security and defines property lines effectively. Referencing a detailed installation guide PDF ensures a professional finish and maximizes the fence’s lifespan, offering peace of mind and value for your investment.

Understanding Local Regulations and Permits

Before commencing any chain link fence installation, thoroughly investigate local zoning regulations and permit requirements. Many municipalities mandate permits for fences exceeding a certain height or located near property lines. Installation guide PDFs often highlight the importance of this step, emphasizing potential fines or removal orders for non-compliance.

Crucially, contact local utility companies to mark underground cables and pipelines before digging post holes. This prevents accidental damage and ensures safety. Detailed installation PDFs frequently include a reminder to perform this vital check. Ignoring this can lead to dangerous and costly consequences.

Regulations may also dictate fence height, materials, and setback distances. Consulting your local building department and referencing a comprehensive chain link fence installation guide PDF will ensure your project adheres to all applicable rules, avoiding future legal issues.

Tools and Materials Needed for Installation

A successful chain link fence installation demands a specific set of tools and materials. Essential tools include post hole diggers, concrete mixers, levels, measuring tapes, wire stretchers, and cutting tools for mesh and top rail. Installation guide PDFs typically provide a comprehensive checklist.

Core materials encompass chain link fabric, line posts, end posts, top rail, tension bands, brace bands, tension wire, and fasteners. The quantity of each depends on the fence’s length and height, as detailed in installation guide PDFs. Don’t forget gate posts and hardware if a gate is planned.

High-quality materials are crucial for longevity. Referencing a detailed chain link fence installation guide PDF will help you select appropriate gauges and coatings for your climate and soil conditions, ensuring a durable and long-lasting fence.

Calculating Material Quantities

Accurate material calculation is vital to avoid costly overbuying or frustrating shortages. Chain link fence installation guide PDFs emphasize starting with a precise fence line measurement. This determines the total length of chain link fabric and top rail needed.

Post spacing is a key factor; installation guide PDFs detail standard spacing (typically 8-10 feet) to calculate the number of line and end posts. Consider corner and gate posts, requiring stronger construction. Accurate post counts directly impact concrete and hardware needs.

Mesh length calculations must account for fabric height and any necessary overlaps. Detailed PDFs often include charts simplifying these calculations. Always add extra material for adjustments and potential errors, ensuring a smooth and efficient installation process.

Determining Post Spacing

Post spacing significantly impacts fence stability and material costs. Chain link fence installation guide PDFs generally recommend 8 to 10-foot intervals for intermediate posts, balancing support and economy. However, terrain variations and wind loads necessitate adjustments.

Corner and gate posts require closer spacing, often no more than 6-8 feet, due to increased stress. Detailed PDFs illustrate how to calculate spacing based on top rail size and gauge of chain link fabric. Proper spacing prevents sagging and ensures long-term durability.

Consulting a PDF guide is crucial for understanding how to account for uneven ground. Adjustments may involve slightly shorter spans or additional bracing to maintain a level and secure fence line. Accurate spacing is fundamental to a professional installation.

Calculating Mesh Length

Accurate mesh length calculation minimizes waste and ensures complete coverage. Chain link fence installation guide PDFs emphasize measuring the total fence line length and adding extra material for tensioning and overlap. Typically, add 5-10% to the total length.

Roll lengths vary, commonly 50 or 100 feet; therefore, determine the number of rolls needed. PDF guides often include charts detailing standard roll sizes and corresponding coverage areas. Consider gate openings when calculating the required mesh length, subtracting their width from the total.

Proper overlap at roll joints is vital for security and aesthetics. Detailed PDFs illustrate techniques for securely joining mesh sections, ensuring a seamless and professional finish. Precise calculation prevents costly overbuying or frustrating shortages.

Step 1: Installing End Posts

End posts are the foundation of your chain link fence, requiring robust installation. Chain link fence installation guide PDFs stress the importance of setting these posts deeper and with more concrete than intermediate posts. Typically, a depth of 24-36 inches is recommended, with a concrete footing extending around the post;

Accurate post placement is crucial; PDFs detail using string lines to ensure straight fence lines. Before pouring concrete, verify posts are plumb using a level. Allow the concrete to cure fully – usually 24-48 hours – before proceeding.

Proper bracing during concrete setting prevents post movement. Detailed guides illustrate using temporary wooden braces to maintain plumb and alignment until the concrete hardens. This initial step significantly impacts the fence’s overall stability.

Step 2: Installing Intermediate Posts

Intermediate posts provide support between end posts, and chain link fence installation guide PDFs emphasize consistent spacing for a uniform look and structural integrity. Typically, posts are spaced 8-10 feet apart, determined by post height and wire gauge.

Installation mirrors end post procedures, though often with shallower concrete footings – around 18-24 inches deep. PDFs highlight the importance of maintaining consistent depth and plumbness across all intermediate posts. Use a string line connected to the end posts as a guide.

Backfilling with concrete and tamping firmly secures each post. Detailed guides recommend allowing sufficient curing time before attaching the top rail and chain link fabric, ensuring a solid foundation for the entire fence system.

Step 3: Attaching Top Rail

Attaching the top rail is crucial for fence stability, and chain link fence installation guide PDFs detail various methods depending on post type. Typically, rails are secured to posts using brackets or tension bands. PDFs emphasize proper alignment to maintain a level top rail, enhancing the fence’s appearance and functionality.

Rails can be cut and joined using sleeves or connectors, ensuring a continuous run. Installation guides often illustrate splicing techniques for longer fence lines. Correctly securing the rail at each post prevents sagging and provides a solid anchor point for the chain link fabric.

Consistent rail height is vital; detailed PDFs recommend using a string line as a reference during installation. Proper attachment ensures the fence can withstand wind and other environmental factors.

Types of Top Rail Materials

Chain link fence installation guide PDFs comprehensively cover top rail material options, primarily focusing on steel and aluminum. Steel top rail, often galvanized, offers robust strength and affordability, detailed in many installation guides. However, it’s susceptible to rust over time.

Aluminum top rail, highlighted in PDF resources, provides corrosion resistance, making it ideal for coastal or humid environments. While lighter and more expensive than steel, it maintains structural integrity. PDFs often include charts comparing the pros and cons of each material.

Vinyl-coated steel is another option, offering a balance of strength and corrosion protection, as explained in some installation manuals. Choosing the right material depends on budget, climate, and desired longevity.

Step 4: Unrolling and Attaching Chain Link Fabric

Chain link fence installation guide PDFs emphasize careful unrolling of the fabric alongside the fence line. Laying it out prevents kinks and simplifies attachment. PDFs detail starting at an end post, securing the fabric with ties – typically galvanized steel or plastic – at regular intervals.

Installation guides stress maintaining consistent tension during this process. The fabric should be taut but not overstretched. PDFs often illustrate proper tie placement: top, middle, and bottom of each post. Joining rolls requires splicing sleeves, clearly demonstrated in visual guides.

Proper tensioning techniques, outlined in PDFs, are crucial for a professional, secure fence. Avoid excessive pulling, which can damage the fabric or posts.

Proper Tensioning Techniques

Chain link fence installation guide PDFs consistently highlight the importance of even tension. PDFs recommend using a chain link stretcher – a specialized tool – to achieve optimal tautness. This prevents sagging and ensures the fence’s longevity. Installation guides detail attaching the stretcher to the fabric and end post, then gradually tightening.

PDFs caution against over-tensioning, which can warp posts or damage the fabric. Visual aids demonstrate the correct amount of stretch – firm, but with some give. Guides also explain how to adjust tension if needed, after initial installation. Consistent tension across the entire length is key.

Detailed PDFs often include torque specifications for tension bands, ensuring a secure and professional finish.

Step 5: Securing the Chain Link Fabric to Posts

Chain link fence installation guide PDFs emphasize using tension bands and brace bands for secure fabric attachment. PDFs illustrate how to weave the chain link mesh through the post’s diamond openings. Tension bands, placed at regular intervals, are then tightened to maintain fabric tension. Installation guides detail the correct band spacing – typically every 12-18 inches.

PDFs show brace bands being used at the end and gate posts for added stability. These bands interlock with the tension bands, creating a robust connection. Guides stress the importance of using the correct band size for your post diameter.

Detailed PDFs often include diagrams showing proper band alignment and tightening sequences for a professional, long-lasting installation.

Using Tension Bands and Brace Bands

Chain link fence installation guide PDFs provide detailed illustrations on tension band application. These bands, typically galvanized steel, wrap around the posts and interlock with the chain link fabric’s diamond pattern. PDFs emphasize using the correct band size corresponding to your post diameter for a secure fit.

Installation guides demonstrate how to evenly space tension bands – generally every 12-18 inches – along the post height. Brace bands, larger and more robust, are used at end and gate posts, providing critical reinforcement. PDFs show their placement alongside tension bands.

Detailed PDFs often include torque specifications for tightening band bolts, ensuring optimal tension without damaging the bands or posts. Proper use, as shown in guides, guarantees a durable and taut fence.

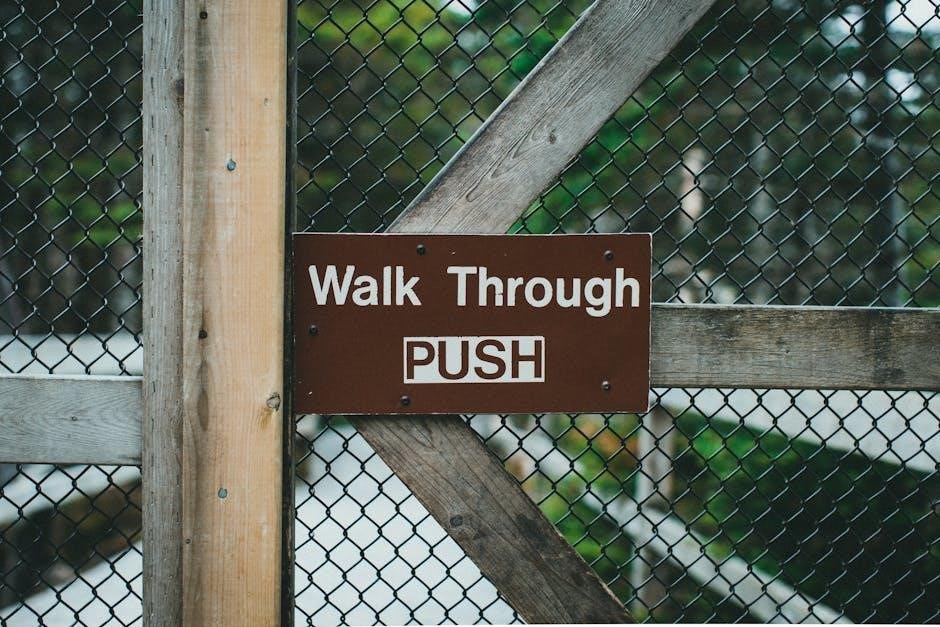

Step 6: Installing Gate Posts and Gate

Chain link fence installation guide PDFs dedicate significant sections to gate post installation, stressing the need for larger diameter posts and deeper concrete footings compared to line posts. PDFs illustrate proper post alignment, ensuring the gate swings freely without binding. Accurate measurements are crucial, as detailed in installation guides.

PDFs demonstrate how to temporarily brace gate posts during concrete setting, maintaining plumbness. Once cured, the gate frame is positioned and secured to the posts. Guides emphasize checking for level and squareness before permanent attachment.

Detailed PDFs often include diagrams showing proper gate hardware placement, ensuring smooth operation. Following these instructions guarantees a functional and secure gate within your chain link fence system.

Step 7: Installing Gate Hardware

Chain link fence installation guide PDFs provide detailed illustrations of latch and hinge selection, categorized by gate weight and frequency of use. PDFs emphasize using hardware specifically designed for chain link, ensuring compatibility and longevity. Installation guides showcase various hinge types – band, strap, and post – explaining their respective advantages.

PDFs demonstrate proper latch installation, highlighting the importance of alignment for secure closure. Guides often include torque specifications for hardware fasteners, preventing over-tightening or loosening. Diagrams within installation manuals clarify brace band placement for added gate stability.

Following these PDF instructions meticulously guarantees smooth gate operation and a secure perimeter. Correct hardware installation is paramount for a functional and lasting chain link fence gate.

Latch and Hinge Selection

Chain link fence installation guide PDFs detail crucial considerations for latch and hinge selection, emphasizing gate weight and anticipated usage frequency. PDFs categorize hinges – band, strap, and post – outlining their load-bearing capacities and suitability for different gate sizes. Installation guides illustrate how to match hinge size to gate post diameter for optimal support.

PDFs showcase various latch types, including fork latches and self-latching mechanisms, detailing their security levels. Guides stress the importance of corrosion-resistant materials, particularly in coastal environments. Diagrams within installation manuals clarify proper latch alignment for smooth operation.

Consulting these PDF resources ensures you choose hardware that guarantees a secure, durable, and long-lasting gate system.

Step 8: Tensioning the Chain Link Fabric

Chain link fence installation guide PDFs dedicate significant detail to proper fabric tensioning, a critical step for fence longevity. PDFs illustrate the use of a chain link stretcher – a specialized tool applying even force across the mesh. Installation guides emphasize the importance of achieving the manufacturer’s recommended tension, preventing sagging and extending the fence’s lifespan.

PDFs demonstrate techniques for attaching the stretcher and incrementally tightening the fabric. Guides warn against over-tensioning, which can damage posts and hardware. Diagrams within installation manuals show correct tension band placement during the process.

Referencing these PDF resources ensures a professionally tensioned fence, maximizing its structural integrity and aesthetic appeal.

Step 9: Finishing Touches and Safety Checks

Chain link fence installation guide PDFs consistently highlight the importance of final checks for safety and durability. PDFs detail inspecting all connections – tension bands, brace bands, and post caps – ensuring they are securely fastened. Installation guides often include checklists to verify each component is correctly installed.

PDF resources emphasize examining the chain link fabric for any damage incurred during installation, addressing tears or kinks promptly. Guides also recommend checking gate operation, ensuring smooth opening and closing with secure latching.

Reviewing these PDFs before considering the project complete guarantees a safe, functional, and long-lasting chain link fence installation.

Chain Link Fence Cost Considerations

Chain link fence installation guide PDFs frequently address budgetary aspects, noting typical costs range from $1,200 to $4,000, with an average homeowner expenditure around $2,100. PDFs detail how height significantly impacts price; taller fences require more materials and labor.

Installation guides emphasize that terrain complexity can increase costs, as uneven ground necessitates additional post adjustments. PDF resources also highlight gate inclusion as a major factor, with gate style and hardware influencing the overall expense.

Consulting a PDF before starting helps homeowners accurately estimate project costs, avoiding unexpected financial burdens during the chain link fence installation process.

Privacy Considerations with Chain Link Fencing

Chain link fence installation guide PDFs often acknowledge the inherent lack of privacy with standard chain link. However, PDFs suggest solutions like adding privacy slats, woven into the mesh, to obstruct views and create a more secluded yard.

Installation guides detail how slat spacing affects privacy levels – closer spacing offers greater obstruction. PDF resources also discuss combining chain link with landscaping, such as hedges or climbing plants, to enhance privacy naturally.

Carefully reviewing a PDF before installation allows homeowners to proactively address privacy concerns, ensuring the fence meets their desired level of seclusion and aesthetic preferences.

Working with Underground Utilities

Chain link fence installation guide PDFs universally emphasize the critical importance of contacting local utility companies before digging. These PDFs stress the need to identify the precise location of underground cables and pipelines to prevent dangerous and costly damage.

Installation guides often include a dedicated section outlining the process for requesting utility locates, typically involving a phone call and marking of underground lines. PDF resources warn against assuming utility locations based on old maps or prior knowledge.

Adhering to the safety protocols detailed in the PDF is paramount, protecting both the installer and the community from potential hazards during the fence installation process.

Resources for Detailed Installation Instructions (PDFs & Videos)

Numerous chain link fence installation guide PDFs are available online from manufacturers and retailers. Peak Fence, for example, provides downloadable PDFs and accompanying step-by-step installation videos accessible on their website, simplifying the process.

Modern Fence Technologies (262-642-9123) also offers updated product information and essential fencing tools, potentially including downloadable installation PDFs. These resources often cover all stages, from material calculation to final tensioning.

A June 27, 2025, video tutorial demonstrates a nine-step installation process, complementing the written PDF guides and providing visual clarity for DIY installers.

Troubleshooting Common Installation Issues

Consulting a comprehensive chain link fence installation guide PDF can preempt many issues. Common problems include incorrect post spacing, leading to fabric sagging, and inadequate tensioning, resulting in a loose fence.

Incorrectly attached tension bands or brace bands can compromise stability. Ensure proper alignment and secure fastening, referencing diagrams within the PDF guide. Difficulty unrolling and attaching the chain link fabric often stems from improper handling – lay it alongside the fence before starting.

If encountering permit issues, revisit local regulations detailed in preliminary sections of some installation PDFs. Always prioritize safety and double-check all connections.

Maintenance and Longevity of Chain Link Fences

A well-installed chain link fence, guided by a detailed installation guide PDF, offers decades of service. Regular maintenance is key to longevity. Inspect posts annually for settling or corrosion, addressing issues promptly to prevent fabric sagging.

Check tension bands and brace bands for tightness, re-tightening as needed. Clean the chain link fabric periodically to remove dirt and debris, preventing rust. Some PDF guides recommend applying a protective coating to galvanized components.

Promptly repair any damage to the fabric, preventing small tears from escalating. Following the PDF’s recommendations ensures a secure and aesthetically pleasing fence for years to come.

Regional Service Areas (Example: Gulfport, MS)

Chain link fence installation services are available in areas like Gulfport, Bay St. Louis, and Ocean Springs, often referencing helpful installation guide PDFs.

Fence Hardware and Technology Updates

Modern Fence Technologies (262-642-9123) has recently expanded its offerings, providing updated fencing tools and essential hardware for chain link installations. These advancements aim to simplify the process, referencing readily available chain link fence installation guide PDFs for optimal results.

New technologies focus on improved tensioning systems and more durable tension bands and brace bands, enhancing the longevity and security of the fence. Manufacturers are increasingly providing detailed PDF guides alongside their products, offering step-by-step instructions and visual aids.

These guides often include information on proper post spacing, mesh attachment techniques, and gate hardware selection, ensuring a professional-quality installation. Accessing these resources is crucial for both DIY enthusiasts and professional installers seeking to stay current with best practices.