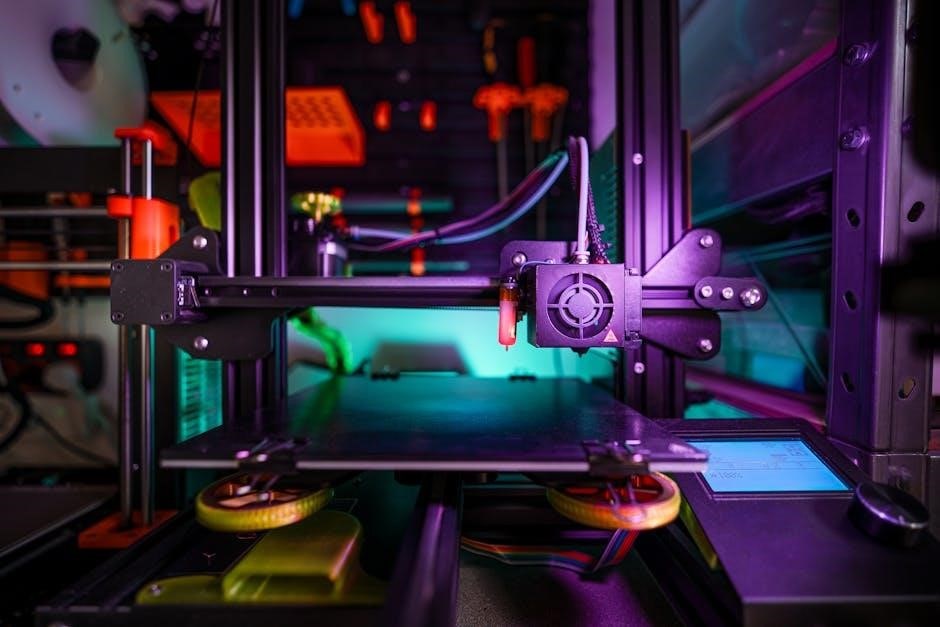

3D printer filament is the material used to create objects in FDM printing‚ available in various types like PLA‚ ABS‚ and PETG‚ each with unique properties for different applications.

Overview of Filament Types

3D printer filaments come in a wide variety of materials‚ each designed for specific applications and performance requirements. The most common types include PLA‚ ABS‚ and PETG‚ known for their unique properties. PLA is biodegradable and easy to print‚ while ABS offers durability and impact resistance. PETG combines the benefits of both‚ providing flexibility and strength. Specialized filaments like Nylon and TPU are used for industrial-grade durability and flexibility. Carbon fiber and wood-based filaments add aesthetic and functional value. BVOH filaments are used as support materials for complex prints. Each type has distinct temperature requirements‚ adhesion properties‚ and warping tendencies‚ making material selection crucial for achieving desired results.

Importance of Choosing the Right Filament

Selecting the right filament is crucial for achieving successful 3D prints. The filament material directly impacts print quality‚ durability‚ and functionality. Using the wrong type can lead to failed prints‚ warping‚ or structural weaknesses. For example‚ PLA is ideal for beginners due to its ease of use‚ while ABS is better for durable‚ high-stress applications. PETG offers a balance of strength and flexibility‚ making it suitable for versatile projects. Proper material selection ensures optimal performance‚ reduces waste‚ and enhances the longevity of printed objects. Understanding the properties and applications of each filament helps in making informed decisions‚ ensuring that the final product meets the desired specifications and requirements.

Key Considerations for Filament Selection

Key considerations include material properties‚ printer compatibility‚ temperature requirements‚ and application needs. Choosing the right filament ensures optimal print quality‚ functionality‚ and durability for specific projects.

Temperature Requirements

Temperature requirements are critical for successful 3D printing. Each filament type has specific extruder and bed temperature ranges. PLA typically prints at 185–235°C extruder and 50–60°C bed‚ while PETG requires 215–270°C extruder and 70–90°C bed. ABS needs higher temperatures‚ around 230–255°C extruder and 95–110°C bed‚ often with a heated chamber. Nylon and advanced materials may demand even higher settings. Proper temperature control prevents issues like warping‚ stringing‚ or clogs. Always consult the filament manufacturer’s guidelines for precise settings to ensure optimal printing results and material performance. Incorrect temperatures can lead to failed prints or damage to the printer.

Bed Adhesion and Warping Prevention

Ensuring proper bed adhesion is crucial for successful 3D printing. Warping occurs when the filament cools and contracts‚ causing the print to detach from the bed. To prevent this‚ use adhesion sheets like boron carbide or PEI‚ and ensure the bed is clean and free of oils. Brims or rafts can also improve adhesion. For materials like ABS‚ a heated bed is essential‚ as it helps maintain even cooling. Additionally‚ adjusting the bed leveling and Z-offset accurately ensures the filament adheres properly. Proper first-layer settings‚ such as increased extrusion width and slowed speed‚ further enhance adhesion. Regularly cleaning the bed and using adhesion promoters like glue stick or hairspray can also minimize warping issues‚ ensuring a strong bond between the print and the bed.

Common Filament Types

Popular filaments include PLA‚ ABS‚ and PETG‚ each offering distinct properties for various applications‚ from durable ABS for functional parts to biodegradable PLA for eco-friendly prints.

PLA (Polylactic Acid)

PLA is the most commonly used 3D printing filament‚ known for its ease of use and eco-friendly nature. Derived from renewable resources like corn starch or sugarcane‚ PLA is biodegradable and emits minimal odor during printing. It prints at relatively low temperatures (185-235°C) and does not require a heated bed‚ making it ideal for beginners. PLA produces smooth‚ glossy finishes and is suitable for detailed prints. However‚ it is brittle and less durable than other materials‚ making it unsuitable for high-stress applications or outdoor use. Despite this‚ PLA remains a favorite for hobbyists and educational projects due to its accessibility and versatility.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a strong and durable 3D printing filament‚ widely used for creating functional and impact-resistant parts. It offers high tensile strength and thermal stability‚ making it suitable for applications requiring durability. ABS prints at higher temperatures (230-255°C) and typically requires a heated bed (90-110°C) to prevent warping. It is commonly used in industrial and automotive applications due to its robust properties. However‚ ABS emits styrene fumes during printing‚ necessitating good ventilation. While more challenging to print than PLA‚ ABS is a popular choice for experienced users seeking long-lasting results. Its versatility and strength make it ideal for mechanical components and prototypes. Proper bed adhesion techniques are essential to achieve successful prints with ABS filament.

PETG (Polyethylene Terephthalate Glycol)

PETG is a versatile 3D printing filament known for its excellent layer adhesion‚ flexibility‚ and resistance to warping. It combines the benefits of PLA’s ease of use and ABS’s durability‚ making it a popular choice for both hobbyists and professionals. PETG prints at a temperature range of 215-270°C‚ with a recommended bed temperature of 70-90°C. Its chemical resistance and ability to withstand moderate heat make it suitable for mechanical parts‚ functional prototypes‚ and outdoor applications. PETG is also less prone to shrinkage than ABS‚ reducing the risk of warping. However‚ it can be more challenging to achieve a smooth finish due to its higher flexibility compared to PLA. Overall‚ PETG strikes a balance between strength‚ versatility‚ and printability‚ making it a reliable option for a wide range of projects.

Other Common Filaments (Nylon‚ TPU‚ Carbon Fiber)

Additional filament types include Nylon‚ TPU‚ and Carbon Fiber‚ each offering unique properties for specialized applications. Nylon is known for its exceptional strength‚ durability‚ and resistance to wear‚ making it ideal for mechanical parts and industrial uses. TPU (Thermoplastic Polyurethane) is a flexible filament‚ perfect for creating elastic and impact-resistant objects like wearables or rubber-like components. Carbon Fiber-infused filaments combine strength and stiffness‚ ideal for structural or weight-sensitive applications. These materials often require higher printing temperatures and specific handling‚ such as controlling humidity for Nylon to prevent moisture absorption. Together‚ they expand the possibilities of 3D printing‚ catering to projects that demand specific mechanical or aesthetic properties beyond standard filaments.

Advanced Filament Materials

Advanced filaments like Nylon‚ TPU‚ and Carbon Fiber offer enhanced strength‚ flexibility‚ and durability‚ catering to specialized applications requiring unique mechanical or aesthetic properties.

Nylon and Its Variants

Nylon‚ or polyamide‚ is a highly durable and versatile 3D printing filament known for its exceptional strength‚ abrasion resistance‚ and flexibility. It is often used for mechanical parts‚ gears‚ and tools that require durability. Nylon filaments are available in various blends‚ such as Nylon 6‚ Nylon 12‚ and carbon fiber-infused variants‚ which enhance stiffness and thermal stability. One of the key challenges with Nylon is its sensitivity to moisture‚ requiring proper storage in a dry environment. Printing with Nylon typically demands higher temperatures‚ around 250-300°C for the extruder and 80-100°C for the bed. Its versatility makes it a popular choice for industrial and functional prints‚ offering a balance of strength and flexibility that other materials often lack.

Flexible Filaments (TPU‚ Flexible PLA)

Flexible filaments like TPU (Thermoplastic Polyurethane) and Flexible PLA are ideal for creating bendable and elastic 3D prints. TPU stands out for its high elasticity‚ impact resistance‚ and durability‚ making it perfect for applications such as wearable accessories‚ flexible hinges‚ and protective covers. Flexible PLA‚ while less elastic than TPU‚ offers improved pliability over standard PLA‚ with good layer adhesion and easier printing. Both materials require specific printer settings‚ such as lower extruder speeds and higher temperatures‚ to ensure smooth extrusion. Proper bed adhesion is crucial to prevent warping‚ often achieved with heated beds or adhesion sheets. These filaments are excellent for projects requiring flexibility and resilience‚ offering a unique combination of strength and malleability that rigid materials cannot provide.

Carbon Fiber and Wood-based Filaments

Carbon fiber and wood-based filaments offer unique aesthetic and functional benefits for 3D printing. Carbon fiber-infused filaments‚ typically mixed with PLA or ABS‚ enhance strength‚ stiffness‚ and durability while maintaining a lightweight structure. These materials are ideal for creating parts requiring high tensile strength and a professional finish. Wood-based filaments‚ such as wood-PLA composites‚ mimic the appearance of natural wood‚ offering a rustic‚ organic look. They are often used for decorative items‚ prototypes‚ and functional parts where aesthetics matter. Both filaments require specific settings‚ such as higher extruder temperatures and careful bed leveling‚ to ensure smooth printing. Proper handling and storage are essential to maintain their quality and performance‚ making them popular choices for advanced printing projects;

BVOH and Support Filaments

BVOH (Butenediol Vinyl Alcohol copolymer) is a water-soluble filament commonly used as a support material in 3D printing. It adheres well to materials like PLA‚ PETG‚ and Nylon‚ making it ideal for complex prints requiring sacrificial supports. BVOH is dissolved in water‚ allowing for easy removal without damaging the primary print. It is often used in dual-extruder printers and is biodegradable‚ offering an eco-friendly solution. Proper handling and storage in a dry environment are crucial to maintain its effectiveness. Other support filaments exist‚ but BVOH remains a popular choice due to its reliability and ease of use‚ especially for intricate designs and overhangs. Its compatibility and solubility make it a valuable tool for achieving high-quality‚ detailed prints. Always ensure correct extruder settings for optimal results.

Filament Management and Maintenance

Proper storage in airtight containers and dry environments prevents moisture absorption‚ ensuring optimal printing performance and filament longevity. Regularly inspect and clean filament spools for dust and debris.

Proper Storage Techniques

Proper storage is essential to maintain filament quality and prevent degradation. Store filament in airtight containers with silica gel packets to absorb moisture and ensure a dry environment. Keep the filament in its original packaging or sealed bags to protect it from dust and humidity. Avoid exposing filament to direct sunlight or heat sources‚ as this can degrade its properties. Label each spool with the material type and purchase date for easy identification. For long-term storage‚ consider using vacuum-sealed bags to minimize moisture exposure further. A cool‚ dry place with consistent temperatures is ideal for storing 3D printing filaments‚ ensuring optimal performance and longevity.

Filament Handling and Humidity Control

Proper handling and humidity control are crucial for maintaining filament quality. Always handle filament in a dry environment to prevent moisture absorption‚ which can cause issues like jamming or brittle prints. Use gloves to avoid oil and dirt transfer from hands to the filament. If filament becomes damp‚ dry it in a low-temperature oven (around 50-60°C) for a few hours before use. Ensure your workspace is humidity-controlled‚ ideally below 50%‚ to prevent moisture absorption during printing. For filaments prone to absorbing moisture‚ like PVA or Nylon‚ store them in airtight containers with silica gel and minimize exposure to air during printing. Regularly inspect filaments for signs of moisture damage‚ such as discoloration or a sour smell‚ and replace them if necessary to maintain print quality and reliability.

Troubleshooting Common Filament Issues

Common filament issues include clogs‚ warping‚ and adhesion problems. Regularly clean the extruder‚ adjust bed leveling‚ and ensure proper filament storage to minimize these challenges.

Addressing Clogs and Blockages

Clogs and blockages are common issues in 3D printing‚ often caused by debris or filament degradation. To address this‚ clean the extruder and nozzle regularly using a wire brush or heated cleaning tool. Ensuring the filament is dry and stored properly can prevent moisture-related clogs. If a clog occurs‚ perform a “cold pull” by heating the extruder‚ then pulling the filament upwards to remove the obstruction. Additionally‚ using high-quality filament and maintaining the correct temperature during printing can reduce the likelihood of clogs. Regular maintenance and proper filament handling are key to smooth‚ uninterrupted printing experiences.

Minimizing Warping and Adhesion Problems

Warping and adhesion issues are common challenges in 3D printing‚ particularly with materials like ABS. To minimize warping‚ ensure the build plate is level and properly calibrated. Using adhesion sheets‚ such as boron carbide or PEI‚ can improve first-layer adhesion. Applying a brim or raft structure in the print settings also helps prevent warping by increasing surface contact. Maintaining consistent chamber or bed temperatures is crucial‚ as sudden drops can cause warping. For better adhesion‚ clean the build plate thoroughly before printing and ensure the first layer height is correctly set. Using filament with minimal moisture content and storing it properly can further reduce warping and adhesion problems‚ ensuring smoother and more successful prints.

Environmental Impact and Sustainability

3D printing filaments vary in biodegradability and eco-friendliness. PLA is biodegradable‚ while ABS is not. BVOH filaments are water-soluble‚ reducing environmental impact. Recycling and reusing materials promote sustainability.

Biodegradability of Different Filaments

PLA (Polylactic Acid) is biodegradable‚ made from renewable resources like cornstarch or sugarcane‚ and can compost under specific conditions. ABS (Acrylonitrile Butadiene Styrene) is non-biodegradable‚ as it is petroleum-based and does not decompose naturally. PETG‚ while recyclable‚ is also non-biodegradable. Nylon and TPU are not biodegradable either. BVOH filaments are water-soluble‚ reducing environmental impact. Choosing biodegradable filaments like PLA is more eco-friendly. However‚ industrial composting facilities are often required for proper degradation. Understanding the environmental impact of each filament helps in making sustainable choices for 3D printing projects. Always consider material properties and disposal methods to minimize ecological footprint. Using biodegradable options when possible promotes greener printing practices.

Recycling and Reusing Filament Materials

Recycling and reusing filament materials is an eco-friendly approach to 3D printing. PLA can be recycled into new filaments or repurposed for other projects. ABS and PETG‚ while harder to recycle‚ can be ground into pellets and reused. Nylon and TPU are challenging to recycle but can be repurposed in creative ways. Many communities and companies offer filament recycling programs. Properly sorting and cleaning materials before recycling ensures better results. Additionally‚ failed prints can be ground and mixed with virgin filament for future use. Reusing scraps reduces waste and lowers material costs. Experimenting with recycling techniques helps promote sustainability in 3D printing. Encouraging a circular economy in filament usage benefits both the environment and the printing community. Always check local guidelines for optimal recycling practices.

Future Trends in Filament Technology

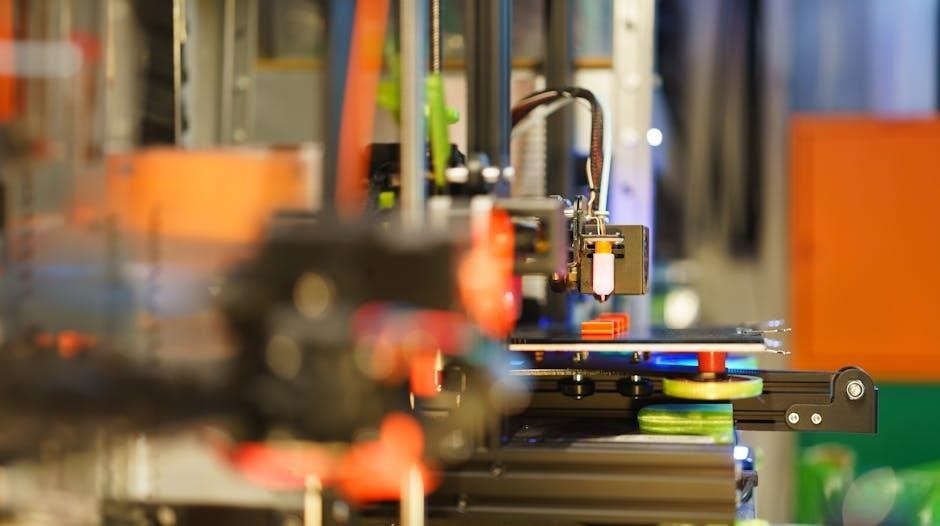

Emerging materials like carbon fiber‚ wood-based filaments‚ and biodegradable options are revolutionizing 3D printing. Multi-material and dual extruder technologies are also expected to advance‚ enabling complex prints with ease.

Emerging Materials and Innovations

Recent advancements in filament technology include the development of carbon fiber-infused materials‚ wood-based filaments‚ and biodegradable options like PLA blends. These innovations enhance strength‚ sustainability‚ and aesthetic appeal‚ catering to diverse applications from industrial manufacturing to eco-friendly projects. Additionally‚ researchers are exploring hybrid filaments that combine multiple materials to achieve unique properties‚ such as flexibility and durability. Multi-material printing is also on the rise‚ allowing for complex structures with varied textures and functionalities in a single print. These innovations are expected to expand the possibilities of 3D printing‚ enabling creators to produce more sophisticated and environmentally conscious products. The future of filament technology promises exciting possibilities for both hobbyists and professionals alike.

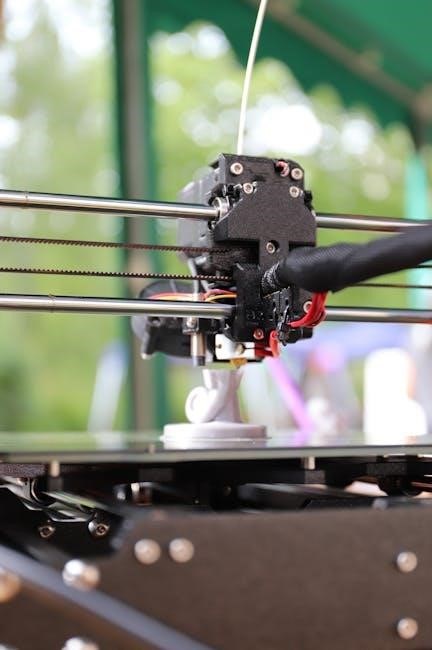

Multi-Material and Dual Extruder Printing

Dual extruder printing enables the use of two different filaments in a single print‚ allowing for color variation‚ material diversity‚ and complex structures. This technology is particularly useful for creating objects with both rigid and flexible components or incorporating support materials like BVOH. Multi-material printing takes this further‚ enabling the use of multiple filaments to achieve specific properties‚ such as embedding flexible TPU within rigid PLA for enhanced durability. This approach enhances creativity and efficiency‚ eliminating the need for post-print assembly. As printers advance‚ multi-material capabilities are becoming more accessible‚ enabling makers to experiment with intricate designs and functional diversity. This innovation is reshaping the possibilities for both hobbyists and professionals in 3D printing.

Selecting the right 3D printer filament is essential for achieving desired print quality and durability. PLA‚ ABS‚ and PETG are the most common materials‚ each with unique properties. PLA is biodegradable and easy to print‚ while ABS offers durability but requires higher temperatures. PETG balances strength and flexibility. Advanced materials like Nylon‚ TPU‚ and Carbon Fiber filaments provide specialized properties for specific applications. Proper storage‚ humidity control‚ and temperature settings are crucial for maintaining filament quality. Addressing common issues like clogs and warping ensures consistent results; Considering environmental impact‚ biodegradability‚ and recycling options is important for sustainability. Experimenting with different filaments and settings helps refine printing skills and expand creative possibilities in 3D printing projects.

Encouragement for Experimentation

Experimenting with different filaments and settings is key to mastering 3D printing. Start with PLA for simple projects‚ then explore ABS for durability or PETG for flexibility. Advanced materials like Nylon or TPU offer unique properties for specialized applications. Don’t hesitate to try new settings‚ layer heights‚ or infill densities to optimize results. Post-processing techniques can also enhance your prints. Keep filaments dry and properly stored to maintain their quality. Embrace trial and error—each failed print is a learning opportunity. Push the boundaries of your printer and materials to unlock creative possibilities and achieve stunning outcomes in your 3D printing journey. The more you experiment‚ the more you’ll discover what works best for your projects.